Category

Circular Saw Blades for Cutting Hard Wood

PRODUCT DESCRIPTION Germany imported steel plate, after tempering heat treatment, the disk body is stable and not easy t

Basic Info

| Model NO. | kws |

| Type | Carbide Saw Blade |

| Brand | Kws |

| Transport Package | Caton Box |

| Specification | 300-96 |

| Trademark | KWS |

| Origin | China |

| HS Code | 82083100 |

| Production Capacity | 10000piece Per Month |

Product Description

PRODUCT DESCRIPTION

Germany imported steel plate, after tempering heat treatment, the disk body is stable and not easy to deform. Ceratizit imported alloys, sandwiches of copper and silver, and automatic CNC welding and grinding machine make the cutter head sharper and more durable. The alternate top bevel tooth design can reduce the resistance, so that the sawing more labor-saving. The inner hole of the center is chamfered, which makes it easier to loading and unloading the saw blade and makes it more beautiful. The wiper can scrape off the grease and moisture in the wood to avoid burning the material due to excessive grease on the saw blade, thereby increasing the life of the saw blade. At the same time, the design of the raker makes the heat dissipation effect better and it is not easy to burn the body. This saw blade is suitable for multi-rip cutting of log and square wood with stable use and high yield.

CHARACTERISTICS

1. Left and right tooth design, optimized cutting angle makes cutting more sharp and smooth.

2. Surface anti-rust treatment to effectively remove glue and sawdust.

3. The scraper blocks the finger-contact of the wood with the saw blade, reducing friction.

4. High-grade saw body provides stable cutting performance and good heat resistance.

5. The plastic protection ring prevents the teeth of the saw blade from being damaged during the movement.

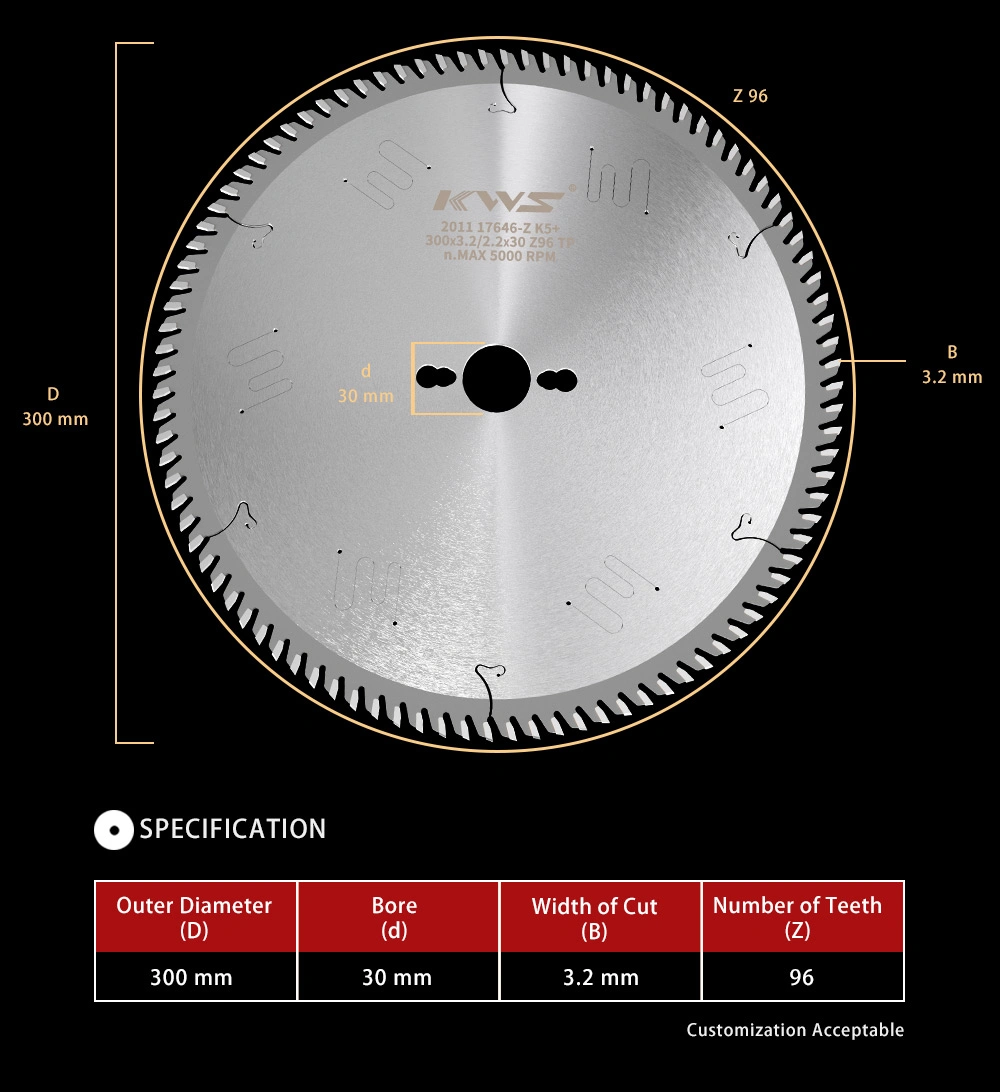

SPECIFICATIONS

| NO. | Diameter | Center Hole | Thickness | Teeth | Keyway |

| 1 | 150 | 45 | 2.2/1.7 | 24+3 | 4*8 |

| 2 | 160 | 50 | 2.5/2.0 | 24+3 | 5*10 |

| 3 | 80 | 50 | 2.5/2.0 | 24+3 | 5*10 |

| 4 | 205 | 50 | 2.5/2.0 | 30+3 | 5*10 |

| 5 | 230 | 40 | 2.2/1.7 | 30+3 | 6*12 |

| 6 | 230 | 40 | 2.5/2.0 | 30+3 | 5*10 |

| 7 | 230 | 45 | 2.2/1.7 | 30+3 | 4*8 |

| 8 | 230 | 50 | 2.5/2.0 | 30+3 | 5*10 |

| 9 | 255 | 50 | 2.5/2.0 | 30+4 | 5*10 |

| 10 | 305 | 50 | 3.0/2.4 | 36+4 | 5*10 |

| 11 | 305 | 70 | 3.0/2.4 | 36+4 | 7*21 |

| 12 | 355 | 60 | 3.2/2.5 | 36+4 | 7*14 |

| 13 | 405 | 60 | 3.4/2.7 | 36+6 | 6*12 |