Category

60Teeth HSS Circular Saw Blade Power Tools for Various Metals

Product Picture Saw Blade Characteristics------Cold saw cutting Metal cold saw concept: In the process of metal sawing,

Basic Info

| Model NO. | 285*2.0*1.7*32*60 |

| Type | Diamond Saw Blade |

| Material | Steel |

| Color | Metallic |

| Certificate | CE |

| Saw Body Shape | Circular Saw |

| Size | Customizable |

| Outer Diameter | 285 mm |

| Blade Width | 2.0 mm |

| Steel Thickness | 1.7 mm |

| Bore | 32 |

| Number of Teeth | 60 |

| Gross Weight Per Unit Product | 2 Kg |

| Adjust | Adjusted |

| Sample Production Time | 5-7 Days |

| Shipping | by Air, by Sea; by Express |

| Sample | Pay Shipping Only |

| Transport Package | Wooden Case |

| Specification | 285*2.0*1.7*32*60 |

| Trademark | Gelisim |

| Origin | China |

| HS Code | 8202310000 |

| Production Capacity | 500000pieces/One Year |

Product Description

| Outer diameter | Blade width | Steel thickness | Bore | Number of teeth |

| 285mm | 2.0 | 1.7 | 32 | 60 |

Product Picture

Saw Blade Characteristics------Cold saw cutting

Metal cold saw concept:

In the process of metal sawing, the heat generated by the saw blade sawing the workpiece is transferred to the sawdust through the sawteeth, and the workpiece and saw blade are kept cool, hence the name cold sawing. Another definition: The processed material object is in a cold state.

Cold saw cutting characteristics:1. High workpiece accuracy, no burrs, reducing the processing intensity of the next process;2. The workpiece will not change its material due to the high temperature generated by friction;3. Low fatigue of operators, providing sawing efficiency;4. Low sparks, dust, and noise during the sawing process;5. Environmental protection and energy conservation.

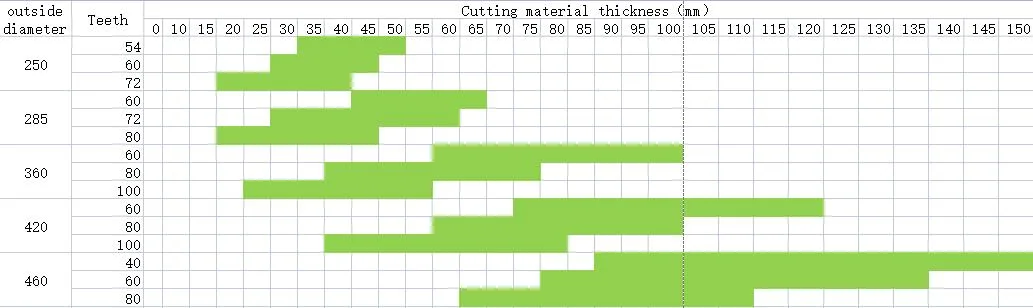

Saw blade selection(For reference only)

If you have any questions about the saw blade, please feel free to contact us, and we have professional personnel to answer them for you

Use And Maintenance Of Saw Blades1. The blade of a circular saw blade is very sharp, and the blade must be protected from damage during installation, movement, and disassembly;2. Before installing the saw blade, debris on the surface of the spindle and flange must be removed, and the flange surface should be flat, clean, and perpendicular to the spindle;3. When installing the saw blade, the screws should not be tightened or loosened too tightly, otherwise it will affect the cutting effect;4. After the saw blade is installed, it should idle for about 30 seconds to ensure correct installation;5. After each use, clean the surface debris and attachments, otherwise it may increase the cutting resistance and energy consumption, and even affect the cutting accuracy.

FAQ1. Can we customize a sample for us to test? Yes, you can tell us the material, size, diameter, etc. for sawing, and we will recommend suitable saw blades for your reference.2. What is the sample fee and can we receive free samples? Our saw blades are all of high quality, so we have to charge a small sample fee. However, we promise to refund the sample fee previously paid when your order reaches a certain quantity.3. What time do you usually ship? If we have the stock of saw blades you need, we usually ship within seven days. If you want to customize or we don't have inventory, it may take 15-30 working days to ship.4. How is your after-sales service? If you have any questions about the saw blade, please feel free to contact us and we will reply to you within 24 hours.